High Energy Density Devices

High Energy Density Devices - Supercapacitors

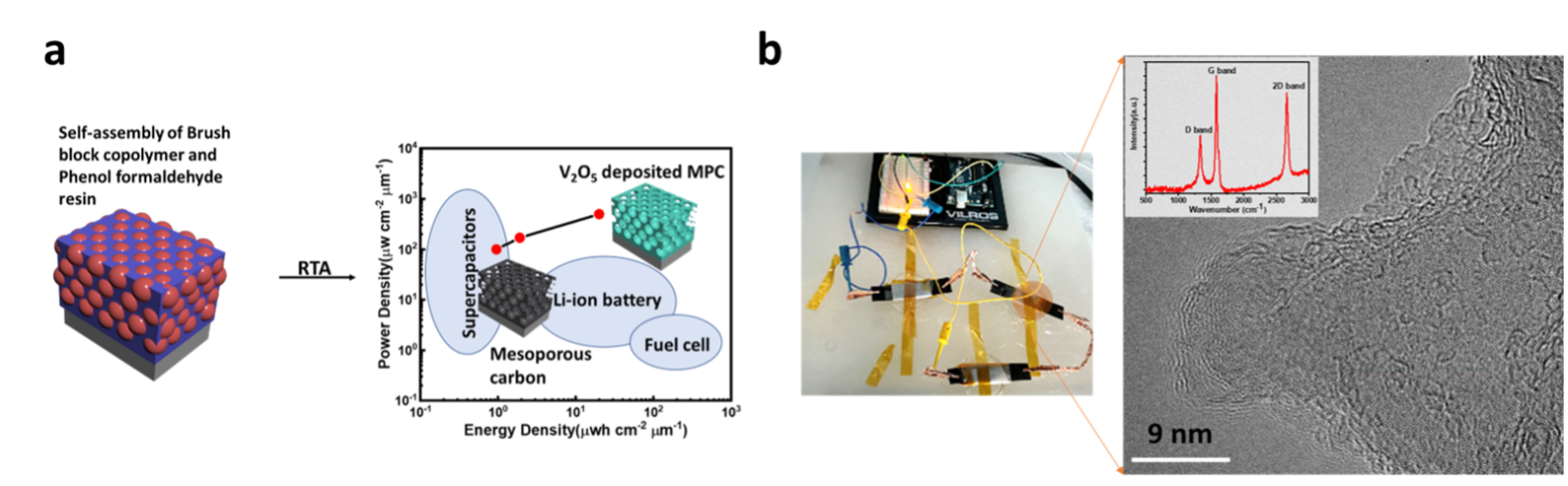

The development of electronic appliances including portable devices and wearable gadgets has increased the demand for miniaturized electrochemical energy storage devices. Micro-supercapacitor power sources are integrated into miniaturized devices due to their ultra-fast charge and discharge rates, high power density, and long cycling life. Porous carbon is the most widely used material super capacitive material as it exhibits attractive properties such as very high surface area, conductivity, and ultrahigh porosity that are important attributes for supercapacitors. Current Carbonization process takes several hours to complete with limited control over porosity and hence is both-time and energy-inefficient. Our focus is to develop a rapid, energy-efficient alternative method for the in-situ preparation of ordered mesoporous carbon, graphene and other electrochemical active material for high performance devices. Project includes preparation of ordered mesoporous carbon with broad pore size tunability, porous graphene derived from brush block copolymer and commercial polymers utilizing scalable fabrication techniques: photothermal processing using Xenon flash lamp, rapid thermal annealing (in collaboration with Prof. Reika Katsumata group).

Figure 1. (a) Schematic diagram of preparation of ordered mesoporous carbon using rapid thermal annealing and its performance represented in the form of Ragone plot; (b) operation of the fabricated supercapacitor device using graphene (left) and HR-TEM of photothermally produced graphene with Raman spectra (inset) of graphene (Right).

Li-ion batteries

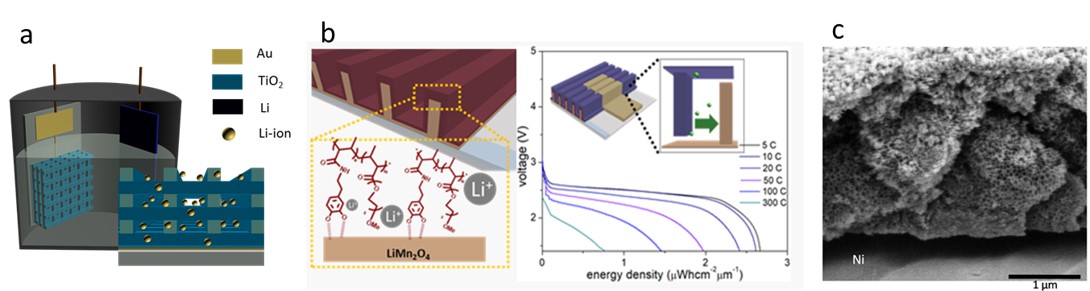

Three-dimensional (3D) microbatteries are key components to self-powered microelectronics. With a total volume smaller than 10 mm3 and electrode’s critical dimensions in the micro/nanoscales, these miniature batteries are promising on-chip power sources. The fabrication of microbatteries imposes not only rigorous material requirements but also the resolution of significant hierarchical processing complexities to integrate elements with delicate 3D topographies and feature sizes spanning from tens of nanometers to millimeter scales. Our focus is on material synthesis and processing to achieve high-performance micro energy storage. Projects include the fabrication of 3D microelectrodes by solvent-assisted imprint lithography, synthesis and deposition of nanoscale polymer electrolytes via solution- or vapor-phase polymerization (collaboration with Prof. Laura Bradley), and the development of mesoporous electrode materials derived from block copolymer/nanoparticle hybrids.

Figure. (a) schematic illustration of a woodpile-like 3D microelectrode. (b) integrated microbattery demonstrating supercapacitor-like power density based on imprinted electrodes and a copolymer gel electrolyte. (c) mesoporous carbon/nanoparticle composite electrode for LIBs.

Roll-to-roll fabrication of carbon films for energy devices

At UMass we recently invented a transformative approach to the preparation of graphitic carbon functional materials that is ideally suited for high rate, low cost R2R manufacturing. Namely, large-area graphitic carbon composites have been fabricated on polymer and metal substrates using catalytic photothermal processing methods. This fabrication scheme enables the selective carbonization of light-absorbing films under mild conditions. The precursor coatings contain phenol-formaldehyde resin carbon precursor, surfactant/porogen and the nanoparticles. Photothermally fabricated graphitic carbon/iron oxide NP composites are promising candidates for high-capacity Li-ion battery anodes.

Figure. R2R fabrication process of graphitic carbon functional films (left), and the fabricated carbon film on copper substrate via carbon precursor coating and photothermal processing (right).

Related Publications:

- Li, W.; Christiansen, T.L.; Li, C.; Zhou, Y.; Fei, H.; Mamakhel, A.; Iversen, B.B.; Watkins, J.J., "High-power lithium-ion microbatteries from imprinted 3D electrodes of sub-10 nm LiMn2O4/Li4Ti5O12 nanocrystals and a copolymer gel electrolyte." Nano Energy 2018, 52, 431-440.

- Li, W., Zhou, Y., Howell, I.R., Gai, Y., Naik, A.R., Li, S., Carter, K.R. and Watkins, J.J., 2018. Direct Imprinting of Scalable, High-Performance Woodpile Electrodes for Three-Dimensional Lithium-Ion Nanobatteries. ACS applied materials & interfaces, 10(6), pp.5447-5454.

- Song, D.P., Naik, A., Li, S., Ribbe, A. and Watkins, J.J., 2016. Rapid, Large-Area Synthesis of Hierarchical Nanoporous Silica Hybrid Films on Flexible Substrates. Journal of the American Chemical Society, 138(41), pp.13473-13476.