Large area roll-to-roll manufacturing

Located on the 4th floor in the Life Science Laboratories the Roll-to-Roll Fabrication facility provides a unique set of custom, moving web-based tools for the translation of advanced materials and nanomanufacturing processes to industrially relevant scalable platforms for the development of next generation life science innovations in biosensors, diagnostics, and platforms for personalized health monitoring. Combined with additional web-based tools for vacuum sputter deposition, reactive ion etching, wet chemistry, and interlayer alignment, providing access to an emerging set of tools not found anywhere else. For more information, visit https://www.umass.edu/ials/roll-to-roll-fabrication

Frontier CoaterThe Frontier coater is a versatile tool enabling solution-based coatings over a range of viscosity and thicknesses for the development of advanced coatings.

|

|

Nanocoater 100The Nanocoater is a versatile tool enabling solution-based coatings over a range of viscosity and thicknesses. UMass researchers have further translated emerging nanomanufacturing processes to this tool including block copolymer self assembly templating and additive driven assembly of functional composites

|

|

R2R Nanoimprint LithographyThe R2R NanoImprint tool provides a unique suite of capabilities enabling innovative process development including patterning across multiple length-scales, and direct printing of a range of materials compositions.

|

|

R2R UV-NIL Tool

|

|

R2R Inkjet Printer/Gravure Coater with Photonic CureThis custom R2R tool provides state-of-the-art capability for development of advanced materials and inks for emerging printed electronic applications. The platform includes Xaar inkjet print head arrays combined with Novacentrix Photonic cure and Adphos Near IR drying.

|

|

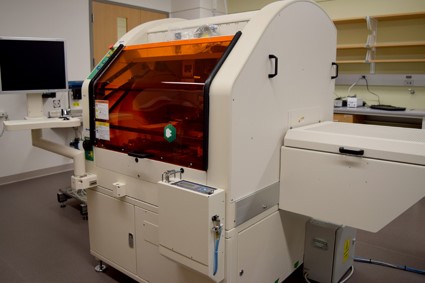

Trion R2R DRIE & IBM SystemThe Trion Deep Reactive Ion and Ion Beam Etcher provides vacuum-based dry etch capability compatible with several substrates (plastic, glass, metal foil). Multiple gases enable versatile etch chemistries for dielectric, metal, and polymer composites.

|

|

UMass Slitter/LaminatorThis custom built atmospheric slitter/laminator tool enables final sizing, slitting and lamination steps to be completed for prototyping and test. (Planned Acquisition)

|

|

Yasui Seiki Mini-LaboYasui Seiki Mini-Labo microgravure tool for coating development on 4” webs. |

|

Besi Datacon 2200 Evo Plus R2R Pick and Place/Bonding Tool for Hybrid IntegrationThe web-based pick and place/die attach tool provides users with an advanced capability to develop methods for flexible-hybrid electronic circuit integration and system prototyping.

|

|

AJA R2R Sputtering SystemThe AJA sputter deposition tool provides industry standard vacuum deposition capability for a range of metals, dielectrics, and magnetic materials. In situ plasma cleaning combined with both RF ad DC pulsed magnetron source provide for state-of-the-art physical vapor deposition.

|