Sensor systems

Fabrication of flexible microfluidic devices via UV-assisted Nanoimprint Lithography

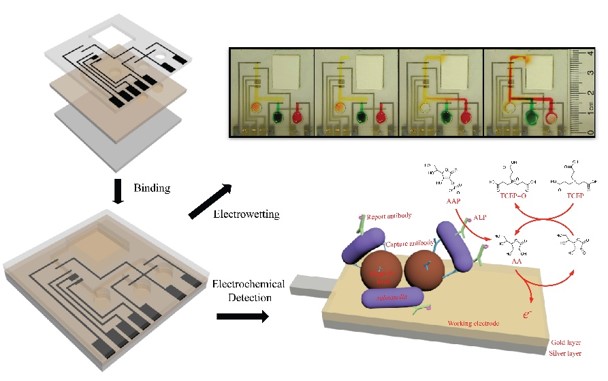

Research in microfluidic biosensors has led to dramatic improvements in sensitivities. However, very few examples of these devices are scalable, preventing this methodology from reaching the hands of potential users. We utilize UV-assisted nanoimprint and inkjet-printing technology to fabricate a flexible microfluidic device containing electrowetting valves and electrochemical sensor. The device is designed to be amenable to a roll-to-roll manufacturing system, allowing for low manufacturing cost. Actuation of the multivalve system with food dye in PBS buffer, for example is performed to demonstrate automated fluid delivery to detect Salmonella in a liquid sample.

Figure. UV-nanoimprint lithography as a tool to develop flexible microfluidic devices for electrochemical detection.

Woodpile electrodes for glucose sensing

Fabrication of detection elements with ultra-high surface area is essential for improving the sensitivity of analyte detection. We utilize nanoimprint lithography as a direct patterning technique to fabricate woodpile nanoelectrode arrays for biosensor applications. With the convenience of sequential imprinting, multilayered woodpile nanostructures with prescribed numbers of layers can be achieved in “stacked-up” architecture and successfully fabricated over large areas. To demonstrate application as a biosensor, an enzymatic glucose sensor is developed. The sensitivity of the glucose sensor can be enhanced by increasing the number of layers, which multiplies surface area while maintaining a constant footprint.

Figure. SEM images of multilayer woodpile electrodes.

Integrated sweat sensors

Integrated sweat sensors on wearable platforms offer an ideal route for noninvasive, continuous measurements of several key biomarkers for human health, including glucose, cortisol, and orexin A. By focusing on scalable and direct-write methods, such as soft nanoimprint lithography, inkjet-printing, screen-printing, and aerosol jet printing, we work towards fabricating low-cost sensors with high-sensitivity. These printed sensors are further integrated into capillary-flow driven microfluidic devices using electrowetting valves for time-sensitive delivery of reagents. This interdisciplinary research is a result of several collaborations with the UMass College of Nursing, General Electric, Air Force Research Laboratory, and National Bio-Manufacturing Consortium. We aim to design real-time sensor systems that are reliable, conformal, and tunable for sweat-sensing wearables.

Figure. Schematic diagrams of integrated sweat sensor design.

Related Publications and News:

- Chen, J., Zhou, Y., Wang, D., He, F., Rotello, V.M., Carter, K.R., Watkins, J.J. and Nugen, S.R., 2015. UV-nanoimprint lithography as a tool to develop flexible microfluidic devices for electrochemical detection. Lab on a Chip, 15(14), pp.3086-3094.

- http://www.gazettenet.com/manufacturing-day-12961602

- https://www.bostonglobe.com/business/2014/08/03/umass-scientists-working-patch-that-measures-stress/X7MEkIZDz3Mwalb1NY3PNL/story.html